603619

Stock code

(%)

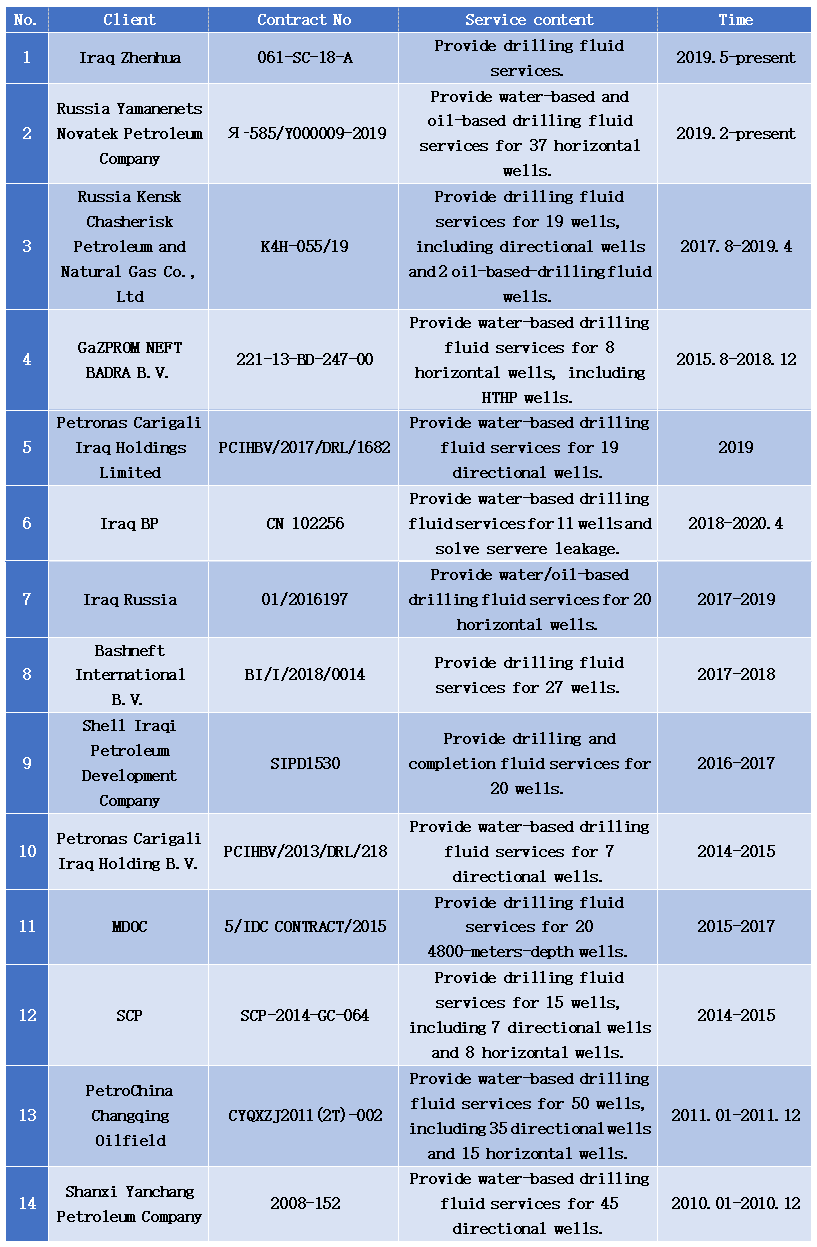

Drilling fluids and oilfield chemicals department focus on technical services such as drilling fluids, completion fluids and oil production chemicals. Its business parts include drilling fluids, completion fluid technical services, drilling fluid solids control, drilling cuttings and other waste treatment technical services, oilfields one-stop services of chemical research, production and application. There are 86 employees who can provide drilling and completion technical services for 20 well teams at the same time. A complete central laboratory was established in Shanghai with R&D and technical support personnel and equipment.

We are committed to seeking and expanding the service market, provide customers with high-quality drilling fluids, completion fluids and other wellbore working fluids technical services. We have successfully provided directional/horizontal wells, ultra-deep wells, high temperature and high pressure wells and other complex wells for domestic and international oil companies in Sichuan, Xinjiang, Changqing and Northeast China, Iraq, Saudi Arabia, Sudan, Kazakhstan. The high-quality service meets the different needs of customers at home and abroad.

We have our own unique technology, characteristic products and services with independent intellectual property rights. We can tailor a safe, environmentally friendly and efficient wellbore working fluid system that meets the needs of different customers according to various operating technical requirements. Meanwhile, we can provide on-site service personnel with international professional and technical levels. We can provide domestic and foreign customers with high-quality drilling fluids, completion fluids and various chemical materials for oil production operations.

1 、Drilling fluids

1.1.Advanced technology concept

· Optimize and customize drilling fluids system to help Party A improve efficiency and reduce costs according to geological lithology, wellbore structure and wellbore trajectory.

· Simplify complex problems and provide Party A with effective underground complex solutions with advanced technology and rich experience.

· What can unique drilling fluid system and additives do:

(1)stabilize borehole

· Effective control of block dropping and collapse

· Inhibit clay swelling

· Maintain the integrity of drilling cuttings

· Prevent hydration and dispersion

(2)increase ROP, decrease NPT

(3)protect environment

(4)protect reservoirs

(5)effectively solve the pressure problem with excellent lubricity

(6)effectively solve the drill bit & downhole drilling tool mud pack problems

(7)significant resistance to high temperature and high pressure

(8)improve solids control efficiency

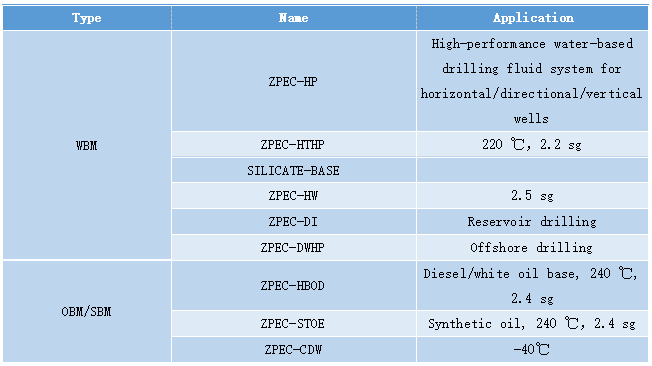

1.1.Unique drilling fluid systems

2、Waste management

3.2.All product catalogs

Catg. | Product tradename | En. Name | Description of material | Functions | Recommended for these systems | Package | ||||

Primary | Secondary | Secondary | WBM | OBM | SBM | |||||

Clay | ZM-MOGEL | Organic Clay | An organically treated montmorillonite mineral clay made by the interaction of hydrophilic bentonite and quaternary ammonium salt cationic surfactants. | V | FL | HTHP | s | s | 25kg/sx | |

ZM-TBODGEL | Viscosified Organoclay | Off-white powder obtained by intercalation modification of refined purified clay and organic covering agent. It can be used as a viscosifier in diesel, mineral and synthetic based drilling fluids of different densities. | V | FL | HTHP | s | s | 25kg/sx | ||

Viscosifier/Encapsulator | ZM-NDPLUS | Anionic Polyacrylamide | Partially hydrolyzed polyacrylamide, white, yellowish or gray powder. It is a high molecular weight, granular polymer which adsorbs at multiple points in clay and shale formations, inhibits clay hydration and dispersion, encases cuttings and stabilizes formations. | SI | FL | V | s | 25kg/sx | ||

ZM-PAC HV | High Viscosity Polyanionic Cellulose | It is a high-viscosity and high-water-soluble cellulose polymer in the form of a white powder. This product has high molecular weight, and it can encapsulate cuttings, reducing dispersion and inhibit the hydration and dispersion of shale, good viscosity-increasing effect, filter cake thinner and denser. | FL | V | V | s | 25kg/sx | |||

ZM-XCD | Xanthan Gum | A premium quality biopolymer powder designed to provide maximum solids suspension and hole cleaning in drilling applications. Small additions into WBM can significantly increase viscosity and suspend weighting materials. This product has very unique properties, which can enable fluids with high shear thinning properties and thixotropy. | V | WBC | s | 25kg/sx | ||||

ZM-RHEO FLOW | Instant Viscosifier for Drilling Fluid | A new type of instant polymer designed to increasing viscosity provide solids suspension in fluid system. Improve mud carrying capacity, compared with xanthan gum, this product has the characteristics of faster dissolution and higher cutting force, more efficient and less additive when mixing in mud. The product is also resistant to salt contamination and the product can still be effective in high salt conditions. | V | WBC | s | 25kg/sx | ||||

ZM-CMC HV | High Viscosity Sodium Carboxymethyl Cellulose | A high molecular weight, high viscosity dispersible sodium carboxymethyl cellulose fluid loss additive, it is slightly calcium sensitive, and is a widely used filtration controller and viscosifier agent in WBM. | FL | V | s | 25kg/sx | ||||

ZM-MORHEO | Rheology Modifiers for OBM | Improve the viscosity of oil based drilling fluid, change the flow pattern of oil based drilling fluid, improve the shear dilution performance of oil based drilling fluid, and is conducive to enhancing the suspension and sand carrying performance of oil based drilling fluid | V | s | s | 200L/dr | ||||

ZM-RHEO | Rheology Modifiers for OBM | A kind of alkanol amide derivative, which is made from polyethylene glycol oleic acid and surfactant as main raw materials through special process. It can increase gel strength in diesel, mineral and synthetic-based systems of different densities. | V | s | s | 200L/dr | ||||

ZM-LVSP | Rheology Modifier for OBM | The molecules of rheology modifier, which can be adsorbed on the surface of organic clay and form a spatial network structure through molecular chain entanglement to improve the rheological properties of OBM at low shear rates. At the same time, the suspension performance of the system and improve wellbore cleaning. Enhance the carrying performance of OBM. | V | s | s | 50kg/dr | ||||

FL Control Agent | ZM-PAC LV | Low Viscosity Polyanionic Cellulose | It is a low-viscosity and high-water-soluble cellulose polymer in the form of a white powder. This product can make the filter cake thinner and denser, low impact on fluid rheology, and it can encapsulate cuttings, reducing dispersion and inhibit the hydration and dispersion of shale, permitting improvement of wellbore integrity. | FL | FL | SI | s | 25kg/sx | ||

ZM-CMC LV | Low Viscosity Sodium Carboxymethyl Cellulose | A water soluble, low viscosity technical grade dispersible sodium carboxymethyl cellulose fluid loss additive, it is slightly calcium sensitive, and is a widely used filtration controller agent in WBM. | FL | SI | s | 25kg/sx | ||||

ZM-FLOHT | High Temperature Modified Starch | A modified starch by inserting hydration groups and high temperature stabilizer to improve the water solubility and temperature resistance (up to 140℃). And ensure its good fluid loss performance under both low and high temperature. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-SMP I | Sulfonated Phenol Formaldehyde Resin | Sulfonated phenol formaldehyde resin is a cation exchange resin designed for extreme temperature drilling environments and salt-gypsum formation to provide effective HTHP filtration control. It performs well in all water-based drilling fluids with chlorides below 120,000 ppm and hardness not exceeding 2,000 ppm with thermal stable up to 232°(450°F). | FL | SI | HTHP | s | 25kg/sx | |||

ZM-SMP II | Sulfonated Phenol Formaldehyde Resin | Sulfonated phenol formaldehyde resin is a cation exchange resin designed for extreme temperature drilling environments and salt-gypsum formation to provide effective HTHP filtration control. It performs well in all water-based drilling fluids with chlorid. It performs well in all water-based drilling fluids and specially in saturated brine with thermal stable up to 180°(400°F). | FL | SI | HTHP | s | 25kg/sx | |||

ZM-LM | High Temperature Copolymer Filtration Reducer | It is polymerized with solvent method through the optimization of monomer of salt resistance and high temperature resistance. The steric hindrance and polymer molecular rigidity are enhanced because of reasonable space volume of the monomers. So it overcome the disadvantages of poor shear performance, poor salt resistance, poor HTHP filtration performance of conventional polymer filtration reducer, is a new polymer filtration reducer with excellent performance. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-HTP | Nitrile-Silicon Polymer Filtration Reducer | It is made by cross-linking polymerization of alkene monomer and silane coupling agent.Due to the introduction of sulfonic acid group, nitrile group, silicone group and other anti-temperature groups in the molecular chain, the product is endowed with excellent anti-temperature and anti-salt performance, with a temperature resistance of more than 240℃ and salt resistance to saturation, and it can be applied to ultra-deep well drilling construction.It is suitable for fresh water, salt water, saturated salt water and sea water drilling fluid. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-PAN | Low Viscosity Copolymer Filtration Reducer | It is an anti-temperature and anti-salt polymer filter loss reducer with ultra-low viscosity effect synthesized from AA, AMPS and DMDAAC as main raw materials, using water as solvent and redox initiation system.It is not only able to effectively reduce the filtration loss of drilling fluids, improve the quality of mud cake, and has strong anti-temperature and anti-calcium salt contamination, but also has a low viscosity effect by strictly controlling the molecular weight of the product, especially suitable for freshwater, saltwater, seawater drilling completion fluids and high-density drilling fluids.It is especially suitable for freshwater, saltwater, seawater drilling completion fluids and high-density drilling fluids. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-DSP | Sulfonate Copolymer Filtration Reducer | It is a sulfonate copolymer polymerized by solution method with the concept of molecular structure design and the preferred selection of temperature and salt resistant monomers.It overcomes the shortcomings of conventional polymer filter loss reduction agents, such as poor shear resistance, poor temperature and salt resistance, and poor effect of HTHP filter loss reduction, etc. It is a new polymer filter loss reduction agent. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-THERM | Sulfonate Copolymer Filtration Reducer | It is polymerized by acrylamide, acrylic acid, 2-acryloyloxybutyl sulfonic acid (AOBS), epichlorohydrin and a new type of cyclic structure cationic monomer.The product has good viscosity increasing effect in fresh water slurry and small viscosity increasing effect in salt water slurry, which can effectively reduce the amount of filtration loss, improve the quality of mud cake, and has certain ability to inhibit clay dispersion.The product has good resistance to temperature and salt. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-SPNH | Sulfonated Lignite | A highly sulfonated lignite polymer designed to improve the filtration and reduce the viscosity & gel strengths of high salt (NaCl) and calcium chloride fluids under high temperature drilling conditions up to 180°(356°F). The product is tolerant of high concentrations of sodium and potassium chloride, as well as calcium chloride and magnesium salts. ZM-SPNH being highly sulfonated, is soluble in high brines where other products such as lignosulfonates and lignites are not effective. ZM-SPNH does not require caustic soda for solubilization as is required for lignites and sulfonated lignins. | FL | SI | HTHP | s | 25kg/sx | |||

ZM-MOFLO | Filtration Reducer for OBM | A high molecular polymer artificially synthesized under high temperature conditions, and its molecular thermal decomposition temperature is as high as 180°C. MOFLO has strong plugging performance and can effectively control the high-temperature and high-pressure fluid loss of oil-based drilling fluid | FL | SI | s | s | 25kg/sx | |||

ZM-MOFLO H | High Temperature Filtration Reducer for OBM | A humic acid amide polymer prepared by a special process. It has excellent lipophilicity and can act as a lipophilic colloid in oil-based mud to make water-in-oil/oil-in-water emulsion more stable, improve temperature resistance of OBM system to 220°C. | FL | SI | HTHP | s | s | 25kg/sx | ||

ZM-TBODFLO | Filtration Reducer for OBM | A resin derivative filtration reducer for OBM, is a black powder solid obtained from lignite through purification, oxidation and hydrophobization. It can be used as a fluid loss control agent in different densities of diesel, mineral and synthetic based drilling fluids. | FL | SI | s | s | ||||

ZM-SOTEFLO | Oleophilic Humic Acid Filtration Reducer | A kind of lipophilic filtration additive with rigid inner core and long hydrophobic chain prepared from humic acid. It does not contain colloid, which is beneficial to reduce paste sieving, solid phase removal, increase ROP, its temperature resistance up to 220°C. | FL | SI | s | s | 25kg/sx | |||

Thinner | ZM-MOTHIN | Thinner for OBM | A polymer prepared by copolymerization of maleic anhydride and styrene sulfonic acid with solvents, initiators, chain transfer agents, etc., with a relative molecular weight of 5000-10000. It has good temperature resistance and salt resistance, can effectively improve the rheology of drilling fluid, and has good wettability. | TH | s | s | 200L/dr | |||

Shale Inhibitor | ZM-CLAYSTOP | Polyamine Inhibitor | A kind of shale inhibitor for WBM, which is a polyamine modified shale inhibitor to provide superior inhibition of reactive clay and reduce swelling of sensitive shales. It can also flocculate any dispersed clays or colloidal particles and aids their removal by solids control equipment to achieve shear-thinning properties. It is suitable in fresh water, seawater and monovalent brines up to 120°C. | SI | s | 200L/dr | ||||

ZM-FT | Sulfonated Asphalt | A high-purity sulfonated asphalt product. It contains high water-soluble and certain oil-soluble components. Compared with ordinary modified asphalt, its molecular chain itself contains multiple adsorption groups, which can form effective plugging on the shale surface through electrical adsorption. It is not affected by formation temperature and asphalt softening point. It has excellent characteristic in drilling fluids, such as plugging and preventing collapse, controlling solids dispersion and improving filter cake quality etc. | SI | FL | s | s | 25kg/sx | |||

ZM-MSH | Nano-Plugging Agent for WBM | A nano-scale deformable high-efficiency plugging agent used in WBM, it has a good effect in dealing with the instability of the wellbore in shale formation, weakly cemented formation. It has a wide particle size distribution, and its particle size is easy to plug the pores and bedding of the shale formation, prevent fluid from intruding into formation, reduce pore pressure transmission, and then stabilizing the borehole. | SI | FL | LCM | s | 25kg/sx | |||

ZM-MSY | Nano-Plugging Agent for OBM | A composite anti-collapse plugging material used in OBM, which can reduce complex problems such as wellbore stability, sticking, and lost circulation encountered when using OBM. | SI | FL | LCM | s | s | 25kg/sx | ||

Emulsifier | ZM-ONEMUL | Integrated Emulsifier | A synthetic low-molecular polymer aggregate with various surface active groups, it does not need to be mixed with other types of emulsifiers to prepare stable and reliable water in oil emulsion drilling fluid using a single agent. | E | SU | s | s | 200L/dr | ||

ZM-EMUL H | Primary Emulsifier | A surface active agent with a variety of surface active groups designed and synthesized through molecular structure design. It is used in combination with secondary emulsifier to prepare a reverse emulsified oil-based drilling fluid system. | E | SU | s | s | 200L/dr | |||

ZM-MOCOAT | Secondary Emulsifier | Secondary emulsifier is a surface active agent with a variety of surface active groups designed and synthesized through molecular structure design. It has a good auxiliary emulsification effect and can make the water in oil emulsion formed by ZM-EMUL H more stable. | E | SU | s | s | 200L/dr | |||

ZM-EMUL | Emulsifier | Emulsifier in diesel, mineral and synthetic-based drilling fluids. | E | SU | s | s | 200L/dr | |||

ZM-PEMUL | Powdered Emulsifier | A solid emulsifier with improved emulsification stability and rheological properties. The hydrophobic end has a branched structure, which can improve the strength and liquid phase viscosity of the oil-water interface film in the water-in-oil emulsion. | E | SU | s | s | 25kg/sx | |||

ZM-STOEMUL | Emulsifier | An oligomeric amine high temperature resistant emulsifier with good emulsification and wetting properties. Its amide, sulfonamide group and branched chain structure ensure the emulsification stability and temperature resistance of drilling fluid. | E | SU | s | 50kg/dr | ||||

LCM | ZM-LCMWD | Lost circulation Material while drilling | It is a combination of granules and polymer, can be used in most drilling fluids in a wide range of formations to seal off the microfractures and form protecting membrane like casing while drilling. The particles are fine and can change their shape under pressures and temperatures. | LCM | BG | s | 25kg/sx | |||

ZM-BRIDGE FLAKE | Calcium carbonate flake | A special acid-soluble reservoir plugging agent, applied to the reservoir drilling leakage plugging effect is outstanding.Its acid solubility can be removed after the end of drilling, which is basically non-polluting to the reservoir and has good reservoir protection ability. | LCM | BG | s | s | s | 25kg/sx | ||

ZM-BHY | Reservoir Protection Material | A dry formulation of bridging, viscosifying, and filtration-control agents. | BG | s | 25kg/sx | |||||

ZM-PSR | Oleophilic Resin Plugging Agent for High Temperature | Oleophilic resin plugging agent for high temperature, is a polystyrene oleophilic resin plugging material, which has good compatibility with OBM and strong temperature resistance. It can effectively reduce the HTHP filtration and sealing fluid loss, and plugging microfractures in the formation can reduce the consumption of drilling fluid, maintain the stability of borehole, and improve the ability of drilling fluid to prevent leakage and collapse. | LCM | s | s | 25kg/sx | ||||

ZM-OBD | Deformable Plugging Agent | Deformable plugging agent for OBM, which can be uniformly dispersed in oil-based drilling fluid and has little effect on rheological and electrical stability. Part of the material softens at high temperature, deforms and compacted to seal formation microfractures, effectively reduce the permeability of the formation, improve the quality of the mud cake, and improve the pressure bearing capacity of the formation. The product can be used up to 180°C. | LCM | s | s | 25kg/sx | ||||

ZM-OBFD | Compound Plugging Agent | Composed of lipophilic expansion and deformation materials, irregular rigid particles, lipophilic fibers and sheet materials, etc. It has strong adaptability to leaky zones and improves the pressure bearing strength of plugging zones. The product can be used up to 120°C. | LCM | s | s | 25kg/sx | ||||

Wetting Agent | ZM-MOWET | Wetting Agent | A fatty acid type oil wetting agent that can effectively wet the weighting materials and drilling cuttings in oil-based drilling fluids, change the lipophilic and hydrophilic properties of the solid phase in the oil-based drilling fluid, improve the lipophilic properties of the weighting materials and drilling cuttings, and is conducive to improving the emulsification stability of the oil-based drilling fluid system. | WT | s | 200L/dr | ||||

ZM-TBODWET | Wetting Agents | Alkanolamide derivative, a wetting agent for OBM, is a product made of alkanolamine and surfactant as main raw materials through a special process. | WT | s | 200L/dr | |||||

Other | ZM-LAE 12 | Biomass Synthetic Base Fluid | A green and environmentally friendly vegetable oil deeply modified product. Different from mineral oil, its molecule is a straight chain structure, no branched chain, and narrow carbon chain distribution. It has excellent safety, lubricity, hydrolysis resistance and viscosity-temperature properties, and has good compatibility with various chemicals such as diesel oil and amide (ester) emulsifiers, and can be used as an environmentally friendly drilling fluid base fluid. | SB | TH | s | 1000L/dr | |||

(1)completed project

(2) letters of commendation

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1