603619

Stock code

(%)

Business Profile

Featured Technologies

• HTHP Well Cementing

• Extended Interval Well Cementing

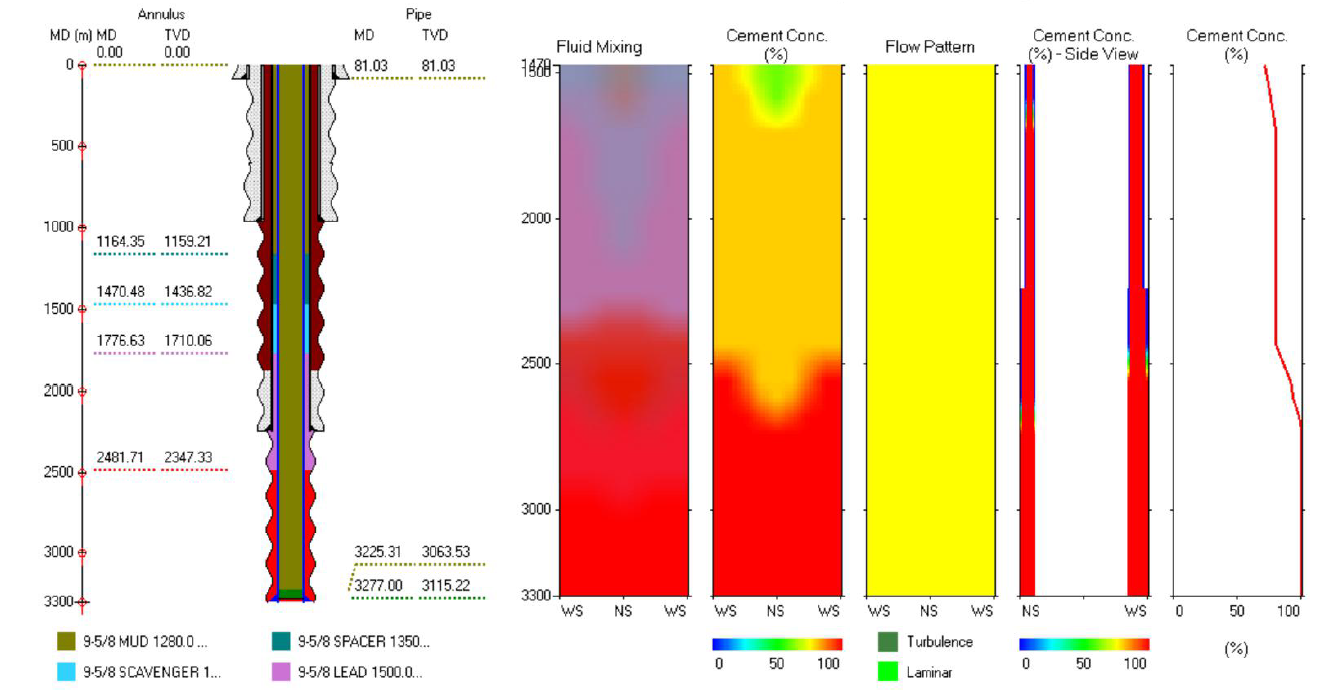

• Complex Hydraulic System Well Cementing

• LP Thief Zone Cementing Technical Package

• Gypsum Well Cementing

• ERD Well Cementing

• High H2S and Anti-corrosion Well Cementing

• Deep Slim Hole and Clearance Well Cementing

• Unconventional Cementing Technical Packages

• Polar Ultra-low Temperature Well Cementing

Case Study

1、GAZPROM IRAQ B.V,Badra oilfield,Iraq

2、Mdoc, East Baghdad oilfield, Iraq

3、 Zhenhua, EBS oilfield, Iraq

4、BASHNEFT INTERNATION B.V,Block-10 oilfield,Iraq

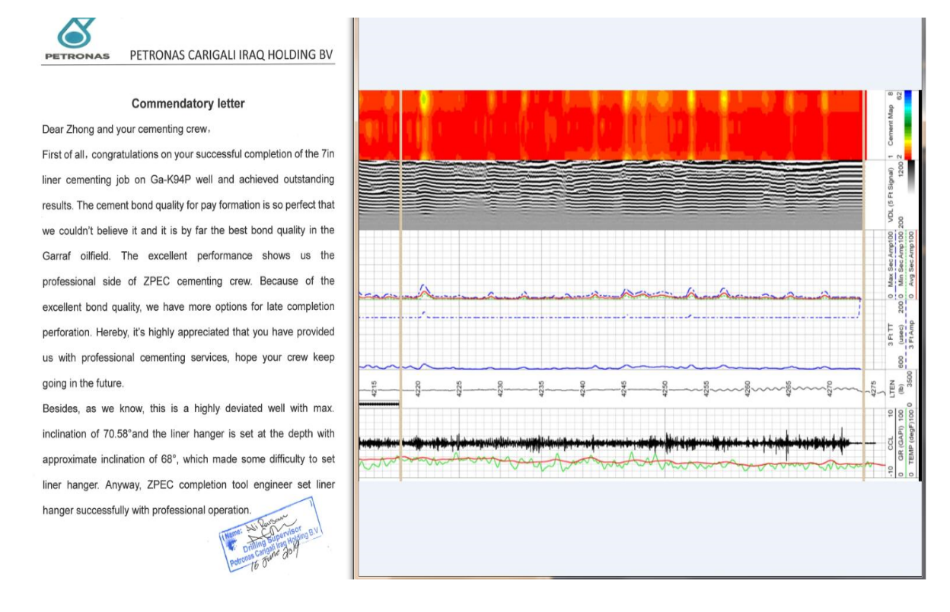

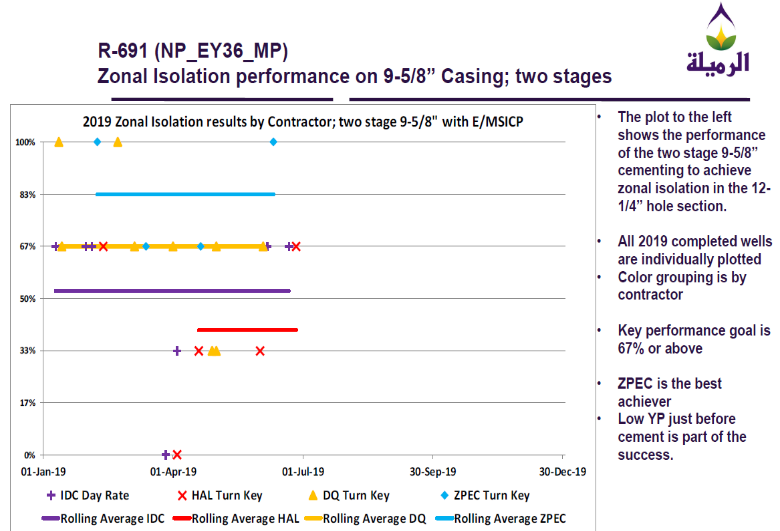

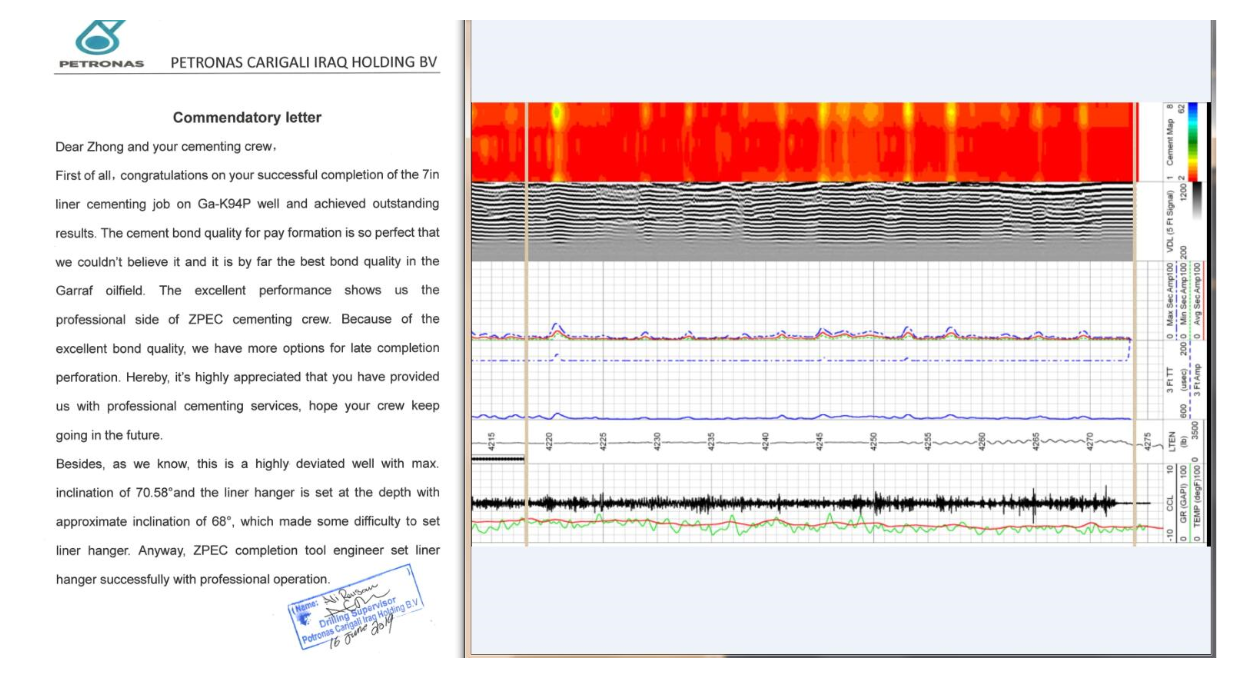

5、PETRONAS CARIGALI IRAQ HOLDING B.V,Garraf oilfield,Iraq

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1