603619

Stock code

(%)

Sichuan ZPEC Kaseum Petroleum Technology Co., Ltd., registered and located at Chengdu, Sichuan province, is a comprehensive high-tech enterprise that integrates product research and development, design, manufacturing, sales and services. The main technology is the electro-mechanical down-hole power system, using high-temperature batteries, high-temperature motors, and gearboxes as power sources to achieve non-explosive, non-hydraulic power, providing customers with efficient, safety, and cost-effective choices. The main products include K-Set Electro-Mechanical Plug Setting Tool, K-Fish Electro-Mechanical Fishing Tool, K-Punch Electro-Mechanical Punching Tool, K-Roller Electro-Mechanical Rolling Tool, K-Mill Electro-Mechanical Milling Tool, K-Cut Electro-Mechanical Cutting Tool, etc.

It has strong technical strength, relying on ZPEC Group, more than 100 wireline and slickline service technicians are available. It has the ability to provide comprehensive on-site technical services for customers. The main technical services include cased hole logging, slickline services and engineering services, such as Electro-Mechanical punching, Electro-Mechanical fishing, conventional perforation, Electro-Mechanical setting bridge plug, pump down perforation, etc.

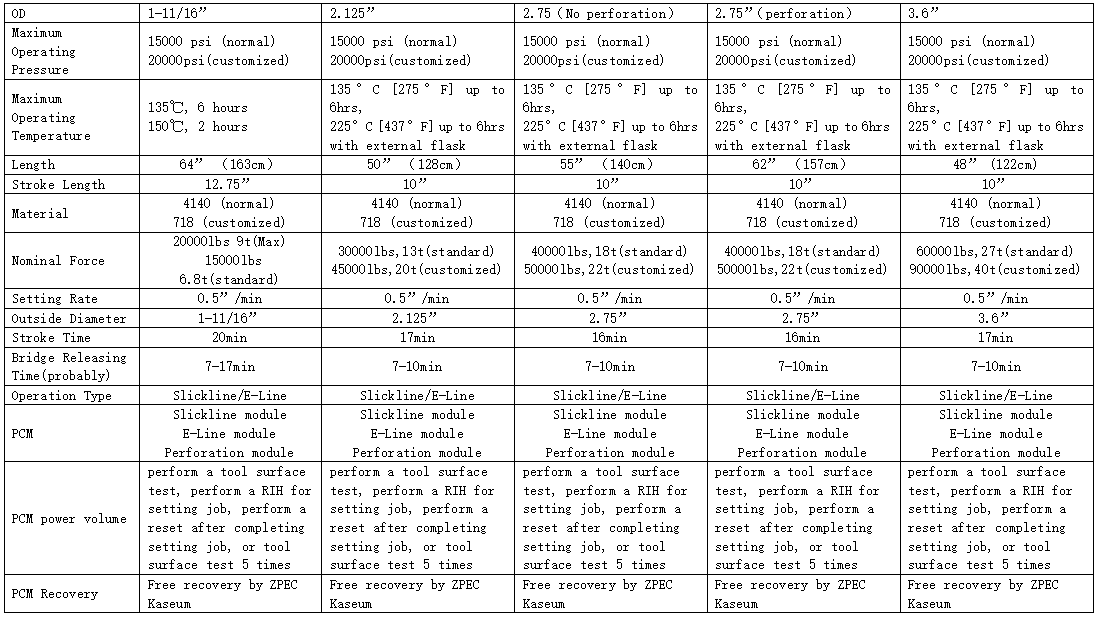

Technical Parameters

2. K-Punch Electro-Mechanical Punching Tool

Using modular structure, the punching module is directly connected to the setting tool, a five-module tool is formed, which contains battery - motor - gearbox - pull rod - punching module. The Punch Tool utilises the K-Set’s 10 inch stroke to both deploy and retract the Punch button in a single stroke.

Application

· Punch hole for tubing/casing, be able to penetrate through alloy tubing or thick wall tubing

Characteristics

· Powered by K-Set as a Down Hole Power Unit, modular structure, safe and reliable, easy to use and maintenance

· Can be used by E-line/slickline/coiled tubing

· Punch automatically by countdown trigger when RIH by slickline

· Real-time control and feedback by E-Line module

· No deformation of pipeline due to sustained large pressure act on the small section

· Suitable for tubing grade J-55, L-80 and P-110

· Punch single or multiple, oriented holes in a single run.

Advantage

· Punch hole and retract the punch button in a single stroke

· Avoid the cost and red tape of gunpowder transportation approval

· No special gunpowder qualification is required for operation

· The operation is extremely simple and compliant with HSE standards

· Compared with gunpowder punching and traditional mechanical punching, cost saving

· The problems such as low success rate of traditional mechanical punching tools and limited target tubing are eliminated

· No impact on annulus, and no injury to the casing

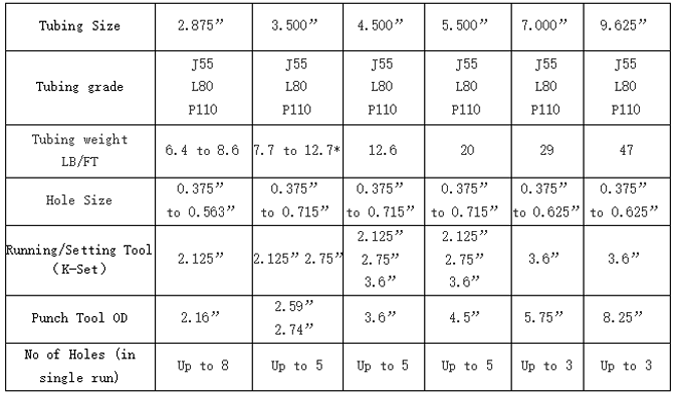

K-Punch Tubing Parameter

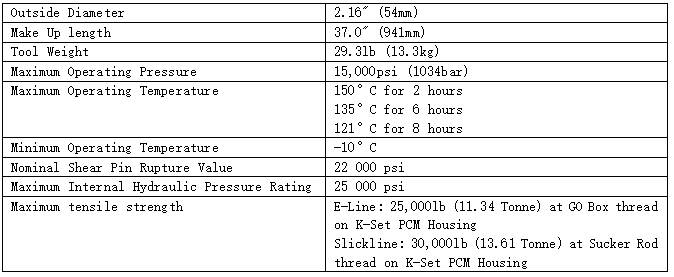

2.875” Tubing K-Punch Technical Parameters

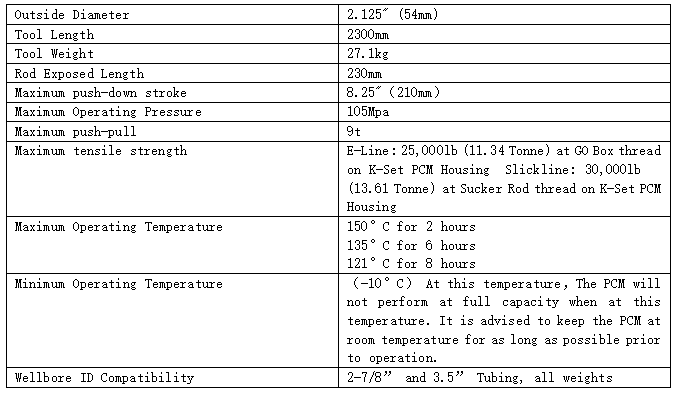

3. K-Fish Electro-Mechanical Fishing Tool

The tool can be RIH by slickline or E-line and can be anchored to the inner wall of tubing or casing. Without any external force and relying on its own battery, it can generate a force of 1-9 tons and complete the fishing job by pulling up or pushing down the overshot. Compared to traditional fishing, it avoids insufficient tension and tools uncontrollable problems, and saves cost.

Application

· Choke fishing

Characteristics

· 2.125'' tool can produce 9 tons of force for pulling up and pushing down

· Hydraulic anchoring and three-way unlocking ensure tool safety

Advantage

· Non-explosive, non-hydraulic power, no wireline, no suppress, only battery needed.

· Unique anchoring slip design, suitable for two-way anchoring, and minimize tubing damage

· The push-down/pull-up instrument can be intelligently switched according to power output and time

· Two weaknesses, three releasing ways to avoid any possible mistakes

· Domestic stock is equipped with motor - gearbox – rod - battery modules, which can be quickly replaced and put into emergency well services

· Alternative to coiled tubing/tubing for salvage operations

2.125” K-Fish Technical Parameters

4. K-Roller Highly-deviated Well Flywheel

The tool can be RIH by slickline or E-line. The patented product specially designed to help the tool string enter into the highly-deviated well. It has been widely used by oil and service companies all over the world. It has the functions of equal aperture perforation, cable signal, magnetic tool center, rotating tubing and etc., to reduce resistance, supporting, suspending and centering. The domestic using record is entering a section with a high deviation of 86 degrees in Jidong Oilfield without assistance of external force (no drive) in 2016.

Application

· Wide application: it is suitable for all well conditions and meets all task requirements of user. It can be applicable to cased hole, open hole, perforation, logging, cable, slickline and tubing.

Characteristics

· RIH speed can reach a rate of 20 m/min

· Customized: customize the wheel with optimal size based on size of tool and borehole to increase the traveling distance.

· Carrying mode: it can be mounted on the surface of tool/tubing/casing, or connected up and down with the tool

Advantage

· Sealed bearing: avoid the blockage by sand, mud and debris in the well and prevent from locking of wheel

· No screw: the flywheel body is free of any screw. Therefore, there is no risk of screw falling in the well.

· Silicone oil injection design: the bearing can be filled with silicone oil before going into the well to achieve the cleaning-sealing-drag reduction effect

· Biaxial rotation: the flywheel can rotate transversely and longitudinally to minimize the resistance while RIH and to move farther in horizontal section.

5. K-Switch Digital Perforating Switch

Kaseum two-in-one electronic switch is a new type of multi-stage ignition switch integrating traditional mechanical switch and electronic selective switch, which is used in multi-stage perforation task. It also has the characteristics of simple installation/operation of mechanical switch, cost saving, and detection and selective electronic switch. And the two-in-one design simplifies the structure and layout of the gun connector from inside to outside, thus reducing wiring time, increasing installation efficiency and reducing cost.

It can directly swap mechanical switches without any extra perforated panels, no need to operate a computer and software, more stable and secure than that of the traditional address selection switch, and cost savings.

Advantage

· The combination of electronic switch and pressure seal plug saves space, simplifies wiring, reduces cost, reduces installation and maintenance cost, and increases perforation safety and efficiency

· No code pairing: no address assignment, same as mechanical switch ignition operation, but can realize all functions of electronic switch, simple design, more stable excitation and safety

· Easy to use: no need to buy separate perforating panel, computer, no need to control software, only 3 switch connections, reduce wiring time and wiring errors

· Its size is absolutely same with that of the mechanical switch. It can be directly exchanged with the mechanical switch. There is no need using detonator design for adapter of perforating gun and only a short and small bypass adaptor is needed.

· Jump function: if the previous level is not successfully fired, it will automatically jump to the next level and wait to be fired

· Temperature resistance 150℃, battery life 48 hours

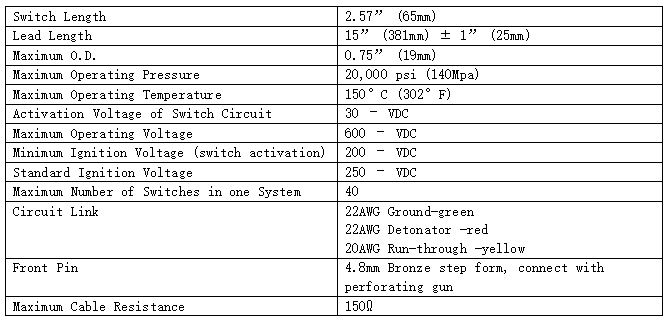

Technical Parameters

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1