603619

Stock code

(%)

ZPEC has a professional informatization research and development team. In recent years, through independent development and actual project application, a series of informatization technology achievements and products have been formed, including:

1. Drilling rig / “Replacing Fuel by Electricity” equipment /top drive online monitoring and diagnosis system

By establishing real-time communication with equipment controllers (such as PLC, inverter, industrial computer, etc.), installing sensors, building networks, etc., online monitoring of the main or critical components of the equipment can be realized, and the data can be displayed and stored in real time. The equipment analysis model realizes diagnosis and early warning, thereby effectively improving the intelligence level of equipment. Equipment management and maintenance personnel only need to use smart terminals (computers, mobile phones, pads) to remotely know equipment operating conditions online in real time, and view early warnings or fault reminders. The system can also be installed and deployed on legacy equipment.

2. On-line metering and monitoring system for energy consumption of drilling rigs (including fuel consumption of diesel generator sets and metering of grid electricity

The power of drilling rigs currently mainly comes from diesel power units, diesel generator sets, natural gas generator sets or industrial power grids. Through this system, the fuel consumption of the power unit or the electricity metered by the grid can be checked online, the energy consumption statistical analysis can be carried out according to the optional time period or a well, and energy-saving operation suggestions can be put forward to maximize economic benefits. The system can also be installed and deployed on old drilling rigs.

3. On-line monitoring and diagnosis system for pumping unit equipment

The remote terminal unit (RTU) specially designed for the pumping unit has the functions of online monitoring, equipment early warning, oil production metering, etc., so as to realize unattended and intelligent monitoring of the pumping unit. The system can communicate with wellhead load, displacement, pressure and other sensors through zigbee or wired way, and can complete indicator diagram collection through load integration, load + angular displacement and other modes. The collected data can be uploaded to the SCADA system through the Ethernet MODBUS TCP protocol. The system has strong functionality, high reliability, flexible application and convenient operation, and can be applied to different types of pumping units.

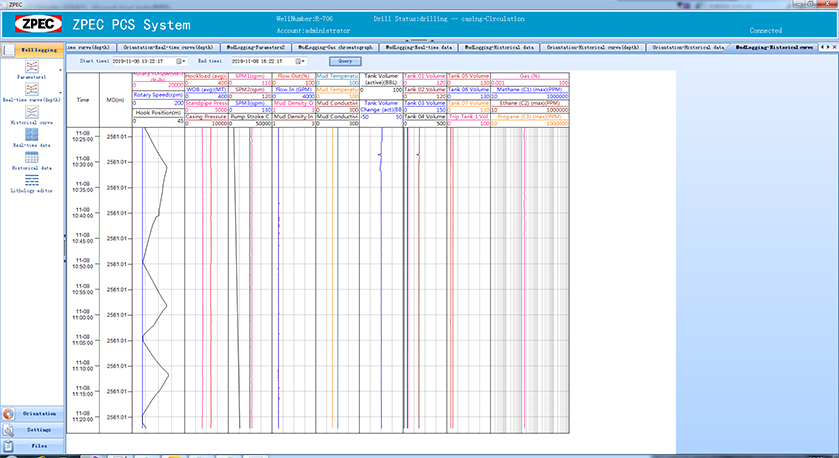

4. On-line monitoring and remote data transmission system for drilling engineering (technology of electric logging, mud logging, drilling and direction, main equipment of drilling rigs, and video monitoring equipment)

In view of the characteristics of the various drilling engineering technology service category, and complex data acquisition and analysis, different systems can be customized to realize online engineering monitoring. The data (including video) transmission needs to be combined with the actual situation of the well site, and different network structure, communication protocols, transmission mechanisms, transmission interfaces, and safety guarantees need to be customized to achieve reliable remote transmission of engineering data.

5. Online monitoring and remote data transmission system for special processes (such as fracturing)

On the basis of realizing online monitoring and data presentation of fracturing equipment, equipment maintenance management, equipment failure prediction, operation process analysis are developed in depth around the whole process of fracturing operation to establish fracturing data base to guide customers to improve efficiency.

6. Drilling engineering report filling management system

It supports the filling of various reports related to drilling engineering (such as drilling daily report DDR, etc.), including data import (or entry), basic information, drilling condition information, operation information, HSE information, drill bit information, BOP information, and mud information, etc. It also supports synchronous uploading of reports and statistics at the central end, which facilitates the filling, archiving and management of drilling reports.

7. Drilling engineering production operation command system (including client, database, and center)

It can realize the digital operation and management of multiple drilling crews by the group (or company), covering the whole process of data collection, data transmission, data analysis, integrated database and interface, real-time monitoring, auxiliary decision-making, and remote command to help realize a scientific operation mode that integrates drilling construction site command and remote operation support center.

8. Oilfield digital construction related systems (covering oil and gas development, oil and gas gathering and transportation and other production management processes)

It includes the automation control system required for oilfield construction (such as DCS distributed control system, PLC control system), SCADA system (such as oil and gas gathering and transportation field), communication network system (building a network to realize the remote transmission of data/video within the oil field coverage);

9. PMS equipment operation and maintenance management system (including client, database, and center)

It can realize the digital management of equipment and materials, including equipment ledger management, material transfer and usage, critical equipment maintenance management, equipment inspection entry and other functions to help enterprises realize scientific management of materials and improve corporate benefits. This system is applicable for equipment owners, operators, maintenance parties, leasing parties and other enterprises.

10. Two-dimensional code material management system.

The system uses two-dimensinoal codes to number and label equipment or materials, and uses two-dimensinoal codes for inventory tracking, destination tracking and other management. This system is applicable for equipment companies, manufacturing companies, warehouses, etc.

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1