603619

Stock code

(%)

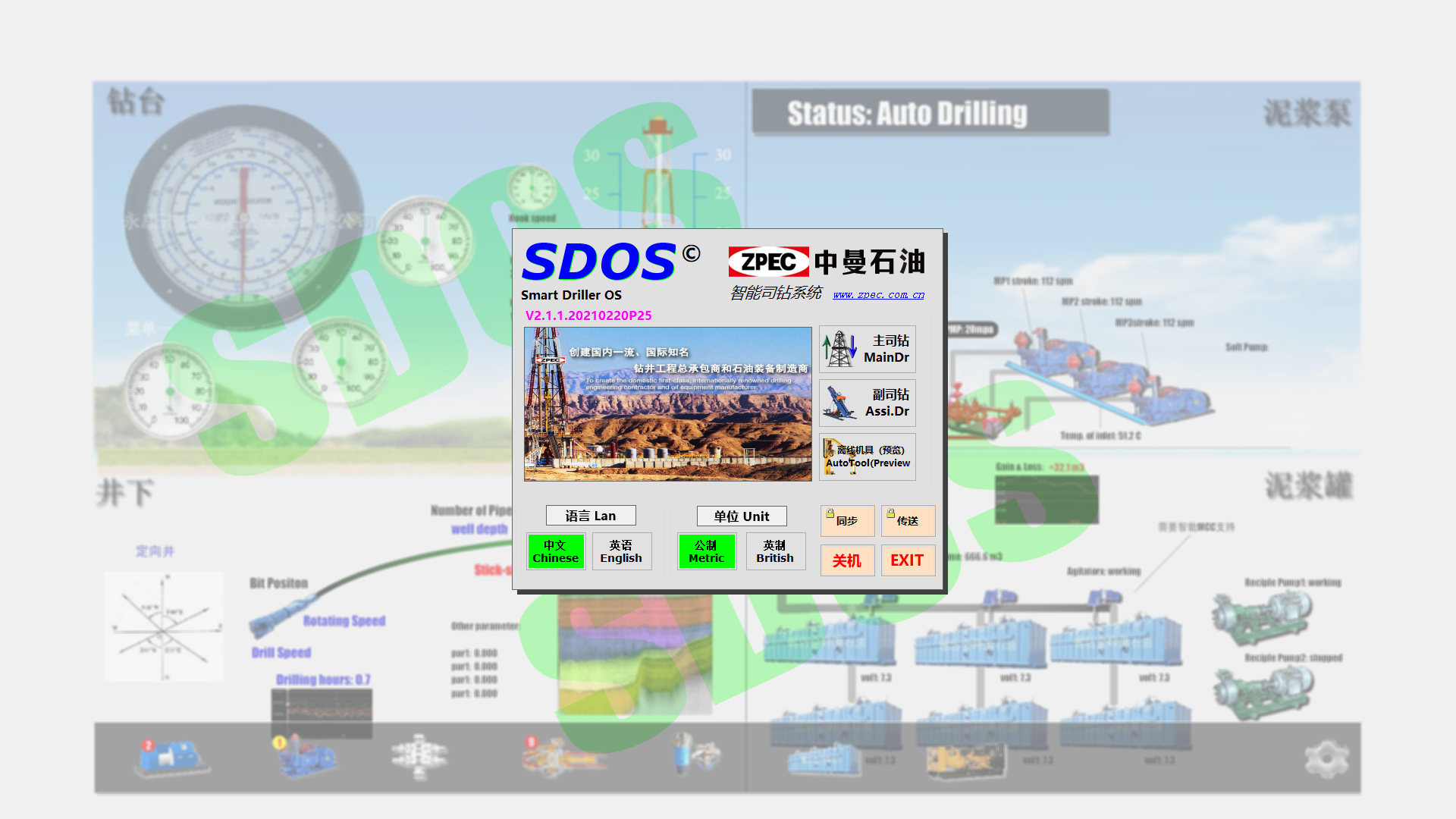

1. ZPEC SDOS (Smart Drilling Operation System):

SDOS means smart drilling control system. It is an integrated system structure that integrates drilling process, drilling monitoring, equipment control, equipment maintenance, safety management, data recording/alarming, intelligency, and expert system. It is an informatized, automatic, and intelligent drilling system according to the modern drilling requirements. The system can also be upgraded on old drilling rigs.

2. The electro-hydraulic control system of automatic equipment (automatic catwalk / pipe handler / iron roughneck, etc.):

The control system for the auto catwalk/pipe handling equipment/iron roughneck has the characteristics of friendly operation interface, complete functions and parameters, convenient operation, and high control precision, which can effectively improve the control level of automatic equipment. The system can be provided in complete sets, or customized software and hardware can be provided according to user requirements.

3. Comprehensive automatic drilling control system:

The limited conditions can be set for automatical drilling. A variety of drilling modes are available: constant rate of penetration (ROP)/constant weight-on-bit (WOB)/constant torque (TRQ)/constant pump pressure (SPP). These modes can be mixed for automatic drilling under different working conditions. A variety of protection or monitoring parameters can be set for the automatic process, and the system automatically optimizes the best control plan to work. In the automatic drilling mode, the automatic reaming function can be turned on. The system can also be upgraded on old drilling rigs.

4. Top drive soft torque optimization control system:

A soft torque system is set on the top drive, which can prevent and reduce stick-slip vibration. The deviation between the instantaneous value of the top drive torque and the actual value is superimposed on the given speed value, and the torque variation amplitude is reduced by increasing or decreasing the top drive speed. This system is set between the top drive controller and the top drive motor, and uses software to optimize the top drive control parameters and then output, so it can also be upgraded on the top drive of the old drilling rigs.

5. Soft pump automatic phase modulation control software for mud pumps;

It can control the coordinated work of multiple mud pumps and pistons to provide a more stable pump pressure, thereby improving drilling efficiency. This software can also be upgraded on the electrical control system of the old drill rigs.

6. Torsion control software for sliding drilling of directional wells and horizontal wells;

This software is an auxiliary tool used in conventional sliding directional drilling. The top drive applies forward and reverse torsion to the drill string, drives the drill string to rotate periodically, releases the friction resistance and torque of the drill string, and relieves the back pressure phenomenon caused by non-rotation of the drill string, to improve the directional efficiency and reduce the risk of drilling operations. This software can also be upgraded on the top drive of the old drilling rigs.

7. Drilling operation simulation training system of drilling rigs:

The driller's chair and its operating devices provided by this system will project the synchronized three-dimensional graphics on the LCD/LED screen to maximize the training effect of drilling operations. This system is based on advanced computer control technology, visualization technology, virtual reality technology and network technology, combined with strict simulation of the actual process of drilling engineering, to provide users with drilling operations (such as tripping, drilling, etc.), equipment failure detection, etc.

8. Intelligent drilling customized software system:

Focusing on areas such as safe drilling, high-efficient drilling, and automatic control of wellhead equipment, we will cooperate with customers to develop intelligent drilling related software systems. It can provide a variety of cooperation methods such as software development, software optimization, software maintenance, database management, and field data collection.

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1