603619

Stock code

(%)

Drilling rig pipe automation products are automatically controlled by the rig integrated control system to realize the automation of pipe transportation in the process of drilling, tripping, and casing running, so as to reduce the labor intensity of workers, reduce the deployment of drilling crews, improve the operation efficiency and reduce the operation risks. Drilling rig pipe automation products are mainly composed of automatic catwalks, drill floor iron drillers, and pipe handling device on monkey board.

The Auto Catwalk is used for transportation of tubulars from the pipe rack area to the drill floor. It has the function of automatic lifting and lowering the drill string. The auto catwalk can be applied to various models of land rigs according to the requirements of clients.

Auto Catwalk - Raised by air winch

It mainly consists of the main body of the catwalk, hydraulic system, and electric control system. The main body of the auto catwalk includes ramp, support, catwalk base, drill string sending device, and dual action air winch.

Auto Catwalk - Raised by Hydraulic Cylinders

It mainly consists of the base, front arm, rear arm, drill string support, skate, hydraulic system, and electric control system.

Different with other auto catwalks, this type of auto catwalk can transmit two or several drill strings once, improving the transportation efficiency greatly. It does not need to be connected to the drill floor when working, so that it is easy to be assembled and disassembled.

The Iron Roughneck is the most advanced tool presently for making up and breaking down of pipes. ZMT120 is specially developed for 5000m ~ 9000m rig. It has a wireless remote control mode and a remote wired operation box control mode and is equipped with a hydraulic handle for repair and emergency operation. The jaw positions are precise and are with the function of multi-position selection. The make-up torque is digitally set and displayed, which can realize precise torque control. The clamping force can be regulated to protect the thread to the largest extent. The spinning wrench has an independent lifting and lowering fuction to enable the equipment to handle special tools.

Pipe Range | 3 1/2 – 10 in | 89-254 mm |

Max. Make-up Torque | 120,000 ft.lbs | 162,000 N.m |

Max. Break-out Torque | 120,000 ft.lbs | 162,000 N.m |

Make-up/Break-out Degree | 60 deg | 60 deg |

Make-up Torque(5’’ DP) | 3000 ft.lbs | 4,000 N.m |

Break-out Torque(5’’ DP) | 80 rpm | 80 rpm |

Spinner vertical stroke | 23.6 in | 600 mm |

Max. working Dia. | 148 in | 3.7 m |

Vertical Travel | 37.4 in | 950 mm |

Hydraulic System Pressure | 3000 psi | 21 MPa |

Hydraulic System Flow rate | 31 gpm | 120 lpm |

Dimension | 70×55×99 in3 | 1780×1390×2510 mm3 |

Weight | 5.3 mT | 11700 lb |

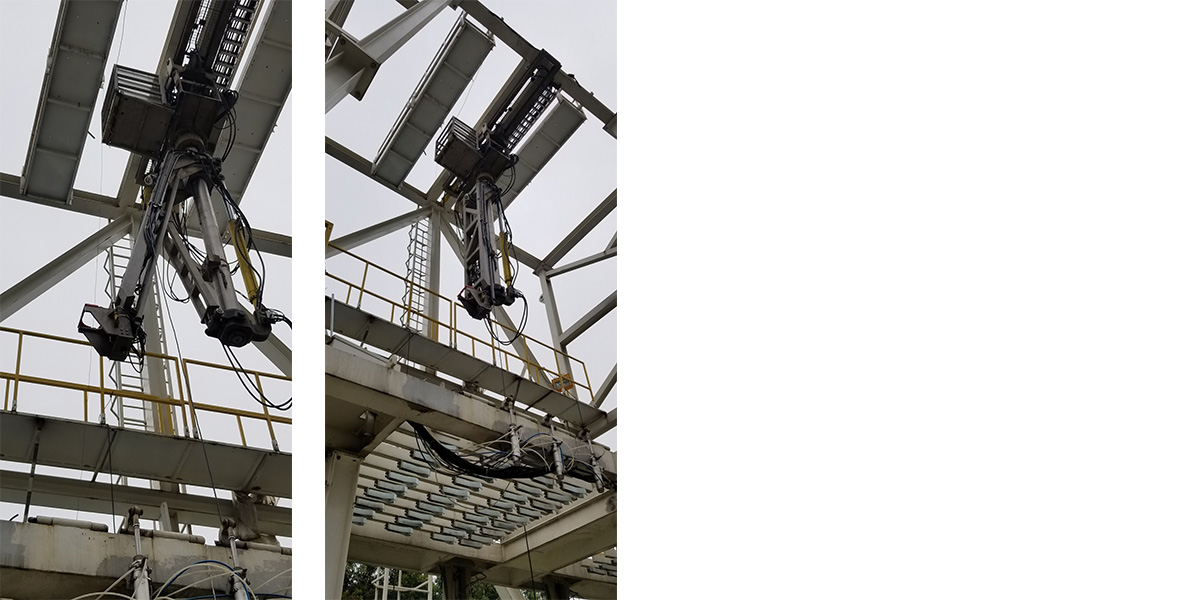

Pipe Handler on monkey board

The pipe handling devices on monkey board are divided into clamping type pipe handling device and supporting type pipe handling device

(1)Clamping type pipe handling device

ZPEC pipe handling device on monkey board adopts innovative technologies, which is applicable for the transportation, racking and storage of drill strings from the wellhead center to the finger beams during the operation of drilling rigs and workover rigs. Working together with the auto catwalk, iron roughneck and hydraulic elevator, it can realize the automatic drilling operation.

(2)Supporting type pipe handling device

According to the mast structure and structure of the hoisting equipment of the drilling rig, the auto handling of three-pipe stand can be realized through the pipe handler on monkey board. It can work together with the top drive during the trip to move the stand from the wellhead to the setback box on the drill floor for placement as order or move the stand from the setback to the wellhead center as order. The equipment integrates the control of electricity, air and liquid, with the feature of high automation and good reliability, which can replace the derrickman on the monkey board.

Six-Axis Robot(Explosion proof)

Product description

Building a modern petroleum and chemical industry system and grabbing the high ground of industry competition are inseparable from the strong empowerment of robot digital intelligence technology.

In response to the forefront of digital technology and industrial development requirements, ZPEC is devoted to exploration into the innovative applications of robots in the high-temperature, extremely cold, and outdoor environments of the oil and gas drilling and exploration industry, especially at high-risk, high-intensity, and high load working condition, the application promotion of "machine substitution for human" to promote the development of automation, intelligence, efficiency, and safety.

Six-axis robot can be widely used in smart drilling rigs and well site automation, not only to replace internal and external fitters to coordinate with automatic catwalk, power mouse hole, iron roughneck, racking board pipe racking manipulator, elevator and other automatic equipment on the drill floor, but also clamp subs, clean threads, and apply thread oil to achieve pipe tripping automation, drill floor unmanned operation and intelligent wellhead operation etc. By using of multi-sensor detection & feedback and robot smart control system, resource loss caused by human operation errors and other factors can be reduced.

Technical Features:

1. Motion range : The maximum arm reach length is 2547mm

2. Load capacity: The actuator end (wrist) can effectively carry 240KG

3. Explosion-proof performance: It can adapt to work in explosive gas environment, and can work at class one and zone two area.

4. Actuator unit: Imported servo motor and drive, high precision, reliability and stability

5. Transmission unit: Imported reducer serving as the key component of precision transmission has a long service life

6. Network bus: one-line cascade, long-distance signal transmission is stable and reliable

Technical Parameters

Robot | ZMR 240/2.55 | ||

Parameters | Rated Speed(°/s) | Range of Motion (°) | |

J1 Axis | 75 | ±160 | |

J2 Axis | 60 | -85 ~ +45 | |

J3 Axis | 60 | -60 ~ +160 | |

J4 Axis | 100 | ±160 | |

J5 Axis | 100 | ±135 | |

J6 Axis | 160 | ±360 | |

IP Class | IP65 | ||

Repeatability (mm) | ±0.2 | ||

Input Voltage | 380V 3AC ±15% | ||

Mounting Type/Temperature /Humidity | Ground / -15~55°C / 0~90% W/O frost | ||

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1