603619

Stock code

(%)

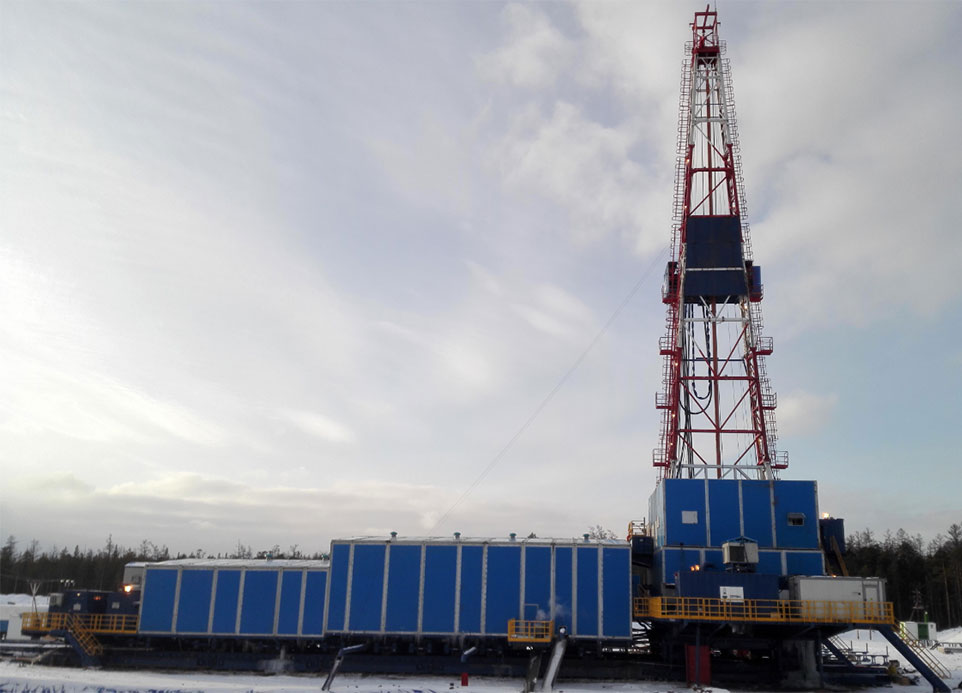

Arctic rigs are specially designed and manufactured cluster rigs for Arctic regions. Rigs are complete with winter thermo shelves, heating and venting systems, securing the stability work of rigs under low temperature environments. The temperature of the working environment is -45℃~+45℃ with a storage temperature of -60℃~+45℃. Polar rigs comply with GOST 12.2.141-99 and the requirements of the petroleum and natural gas industry security requirements ПБ 08-624-03.

According to the characteristics of the high cold environment, the material, lubrication seal, hydraulic transmission, electrical transmission control and so on to carry out a comprehensive characteristic design, the mechanical structure of the key parts are using low temperature resistant materials, for the lubricating oil box are using automatic temperature control heating device.

A variety of heating methods and parallel partition blocks are used for precise thermal insulation heating to ensure that the temperature on the drilling floor is ≥0℃ and the temperature in the insulation shelter is ≥10℃, so as to improve the heating efficiency.

The power supply system can be supplied by diesel generators or industrial power grids, and the two can be interchangeable.

Model | Nominal Drilling Depth | Drawworks Power | Max. Hook Load | Mud Pump Power | Power Supply |

ZJ30 | 3000m | 600kW/800HP | 180mt | 2×800Hp | 2×1000kW |

ZJ40 | 4000m | 1000kW/1340HP | 250mt | 2×1000Hp 2×1600Hp | 3×1000kW |

ZJ50 | 5000m | 1200kW/1600HP | 320mt | 2×1600Hp 3×1600Hp | 3×1200kW |

ZJ70 | 7000m | 2000kW/2680HP | 450mt | 3×1600Hp | 4×1200kW |

ZJ90 | 9000m | 3200kW/4300HP | 675mt | 3×1600Hp 2×1600Hp+2200Hp 3×2200Hp | 5×1200kW |

ZPEC pawl slide rail polar rig apply to Yamal region with polar low temperature environment, ratchet slide double track layout, insulation shed modular integrated design, which can be moved along with the rig. The rig is designed as compact structure, modular disassembling and transportation.

Product features:

· Equipped with main and auxiliary pawl sliding rail moving device, the main track can move in x-Y direction, which can meet the requirements of drilling line Wells, accelerate drilling efficiency and reduce operating costs.

· Both mast and substructure rig up and down adopt hydraulic cylinder.

· Digital control mode, equipped with ZPEC-SDOS operating system to realize the automatic function of the machine and tools.

· Meet the requirements of -55℃ -- +40℃ operating environment.

The rig is developed by ZPEC apply to low temperature area adopts low temperature resistant and high strength wheel and rail materials. All components are installed on heavy rail, the rig is moved by hydraulic cylinder push, which is suitable for cluster well operation.

Product features:

· Modular solid control layout design, electric control room can be stacked up enable to save drill floor space.

· Mast can be applicable to K type, narrow type, telescopic type, etc. The substructure can be applicable to box on box type, sling shot type and swing up type, etc.

· The rig can be raised up with hydraulic cylinder which is reliable mature technology.

· Digital control mode, equipped with ZPEC-SDOS operating system to realize the automatic function of the machine and tools.

The new generation of low-temperature drilling rig, integrating innovation, optimization and upgrading. It adopts a slide-rail type double-track moving structure. All modules of the drilling rig are placed on the track to meet cluster well operations. At the same time, the thermal insulation shed adopts a combination design, integrating the drill floor thermal insulation wall plates and the driller's cabin, and integrating the solid control area thermal insulation shed and the solid control tanks, which has a compact structure and is convenient for disassembly and assembly. This innovative design concept not only solves the problems of many modules, heavy weight, easy wheel derailment, and inconvenient installation of the insulation shed of the conventional train-type low temperature rig, but also reduces production and operation costs, achieving a win-win goal with customers.

· Adopt slide-rail type moving device, which has simple structure, and is quick for installation;

· The thermal insulation wall plate of the drill floor is integrated with the driller's cabin to meet the requirements of fast installation and moving of the drilling rig;

· The integral design of the insulation shed of the solid control area and the solid control tanks is compact, and can be transported as a whole or separately;

· The mast and the substructure are arranged at 90 degrees, with an open front field space, which is convenient for changing well locations;

· The mast and substructure are raised with hydraulic cylinders, with features of compact structure and convenient installation and lifting;

· The integrated design of the driller's cabin and the dog house effectively utilizes the area of the drill floor and also enhances the insulation effect of the rooms;

· The mud pumps adopt direct drive technology, the equipment is light and compact, with few failure points and is easy for maintenance.

Nominal drilling depth m | 5000(5’’ dp) |

Max. hook load kN | 3200 |

Hook speed m/s | 0~1.67 |

Wireline of travelling system | 12 |

Dia. Of drilling wirelines mm | 35 |

Drawworks power HP | 1500(2档无极调速) |

Drill floor height m | 10.5 |

Effective height of mast m | 45 |

Opening of rotary table mm | 952.5 |

Power of each mud pump HP | 1600 |

Electrical transmission type | AC-VFD-AC |

Ambient temperature of drilling rig operation | -45℃~+45℃ |

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1