603619

Stock code

(%)

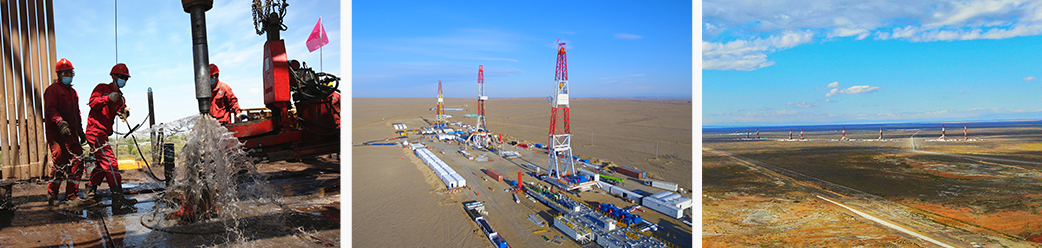

Party A is the CNPC Tarim Branch. The drilling project of Tarim Oilfield is faced with the difficulties of complex geological structure and formation pressure system, deep salt layer, development of both composite salt paste layer and huge thick mudstone, deep high pressure and low permeability, carbonate reservoir with development of weathering crust, and containing H2S and CO2 in some areas etc. By applying multiple advanced technologies and tools including radical drilling parameter design, Power-V, optimized composite drill bits (Liger type), heterotypic-teeth drill bits, reasonable use of high-pressure injection, well drilling & completion liquid with nanotechnology, etc., ZPEC drilled and completed the first well named Keshen 13-2 well which was prognosed at total depth of 7486m for projecting construction period of 286 days. But finally, ZPEC achieved the actual well depth of 7483m for construction period of 243 days, which reached a record of the shortest well construction period in the same block. Through this milestone achievement, ZPEC has established an excellent brand image in the Tarim oil field and also highlighted its top level of ultra-deep well drilling technology.

Deep complex wells have multiple problematic issues such as wellbore high temperature and high pressure, longitudinal variable formation pressure, complex well structure, high well control risk and poor drillability and so on. ZPEC has completed more than 50 deep complex wells in the Tarim (China), Junggar (China) and Badra (Iraq). ZPEC has received high praising from Party A owing to its well-known fast drilling speed, and complex and accurate processing.

The Badra Oil Field in Iraq has complex and changeable formation pressure profile with a high-pressure saltwater layer and very hard formations. The wells were designed to be 7-layer casing well structure. Thus, the drilling difficulty is extremely high. A well-known international oil service company completed two wells with a drilling cycle of nearly 500 days. After winning the bid, ZPEC generated a series of supporting technologies such as high temperature and high pressure deep well cementing technology, small gap well cementing technology, deep hole reaming technology, high grinding formation acceleration technology and broken formation coring technology by having actively analyzed data and strengthened technical breakthroughs. The drilling cycle was gradually shortened from 300 days to 180 days, which ZPEC has gained a high international reputation.

It’s known that super long horizontal-section horizontal wells have high hole-cleaning requirements, large friction, easy to collapse and casing difficulties. However, ZPEC has completed more than 10 horizontal wells with over 2000m horizontal section in Xinjiang Mahu Oilfield, Inner Mongolia Surige Gas Field, Gansu Qingyang through careful constructions, precision countermeasures and applying advanced horizontal section friction and collapse prevention process.

The total depth of Well AHHW2032 completed by the Zhongman Rig 7 crew is 5438 meters with a horizontal section length of 2000 meters., and drilling cycle of 33.38 days, which has reached a record of the shortest three-spud-in drilling period in Block 2 of Mahu Oilfield. The total depth of Well 014-113H2 drilled by the Zhongman Rig 15 crew is 5425 m with a horizontal section length of 2500m and drilling cycle of 40 days, which has been highly praised by Party A.

The Well AHHW2030 constructed by the Zhongman Rig 11 crew has a well construction cycle of 32.04 days which has broken the record of the shortest well construction cycle for the 2000 m long horizontal section in the whole Mahu block. The Zhongman Rig 11 crew has been awarded the title of "Ace Drilling Rig Crew" by Party A owing to such outstanding achievement.

The construction site of the Russian oil project is located in Yamarneniez Autonomous Region of Qiumen Prefecture, Russia with the lowest temperature of 62℃. There is varying-thickness permafrost in each oil block in this area. Since the drilling activities started from 21st December 2017, 61 cluster horizontal wells have been drilled and completed, of which the deepest total depth is 3944 m and the longest horizontal section is 1355 m.

Through scientific research breakthroughs on the engineering technical problems during constructions, ZPEC has gradually developed technologies including the permafrost low temperature drilling fluid system, oil based drilling fluid system, permafrost cementing water mud system. These technologies have achieved very good results in practical application and also solved the drilling problems on negative large displacement, long inclined well section and large torque horizontal well. The drilling / construction period of the horizontal well in the Kenskchasheri block being operated by Rosneft was reduced to the fastest period of 12.13 / 20 days from 33.66 / 45.49 days in the first well. The drilling / completion period of Novatek wells was decreased to 23.76 / 29.22 days from 41.42 / 51.63 days in the first well., These have broken the record for the oil field.

Since the Zhongman Egypt project entered the Egyptian well market in 2016. The drilling area of the Egyptian Water Wells project is located in the hinterland of the largest Sahara Desert in the world. The climate is dry and hot, with great wind and sand, and the living and working environment is very bad. However, under the extremely harsh natural conditions, it left the great performance of ZPEC.

Up to now, a total of 214 Wells and 126,421 m footage have been completed to help the "barren land" to develop agriculture. The journal "Large Egyptian desert will eventually become fertile land" was published in the People's Daily in 2019. The Zhongman drilling team is known around the Sahara Desert, Egypt, and North Africa.The Zhongman Egypt Project started to enter the Egyptian water well market from 2016. The drilling area of the Egyptian Water Well Project is located in the central region of the Sahara Desert, the largest desert in the world, where the climate is dry and hot, and wind and sand are strong. Thus, the living and working environment in the project area is very bad. However, it still left the footpath of great performance of ZPEC under such extremely harsh natural conditions.

Up to now, a total of 214 Wells with 126,421 m footage in aggregate have been completed to help the community in "barren land" to develop their agriculture. The journal titled "Large Egyptian desert is eventually becoming fertile lands" was published in the People's Daily in 2019. As such, the Zhongman drilling team is well known around the Sahara Desert, Egypt, and North Africa.

The Zhongman Russia project is located at the region between north latitude 63-67 degrees in the Yamarnenez Peninsula of Russia, where the Nord and Novatek projects are situated in northernmost of this region. The region has complex surface conditions with lush vegetation and crisscrossed rivers. The mobilization, installation and logistic material organization are extremely difficult so both personnel shifts and logistic supplies can only be transported by helicopters.

In the swamp area of the Novatek project, 12 horizontal wells have been completed with an average completion cycle of 32.3 days. As the only Chinese enterprise engaged in drilling engineering in this region, ZPEC has shaped the "Golden Signboard" of Chinese drilling services with its outstanding performance and excellent production organization capacity.

Large-slope and large-displacement directional wells usually have such technical issues as sand-carrying difficulties, large friction, easy pressure-held and easy hole-collapsing in underground, which are recognized to be the well type with a high risk of drilling-stuck. Since 2010, ZPEC has successfully completed over 100 large-slope wells with the slope of greater than 60 degrees by applying its own technologies including the hole-cleaning technology, rotary-guidance technology, nano-blocking and anti-collapse prevention technology in Ordos Basin (China), Junggar Basin (China), Tarim Mountain-front Block (China) and Garraf Oilfield in Iraq.

In the Garraf oil field in Iraq, the Rig 25 has completed 10 large-displacement wells with the slope of greater than 60 degrees, of which the maximum slope is 71 degrees in K94P well and the horizontal displacement is 3500m. This has reached the best record of the country of Iraq. In Surig (China), the Su 14-7-14xh1 well completed by the Rig 8 has achieved the maximum slope of 78 degrees and also steadily drilled through the 300m easy-collapsing mudstone section. This well was completed safely and efficiently by applying nano-blocking technology.

The piedmont structure of Tianshan Mountains has always been regarded as the highest point of drilling engineering technology because there are many geological and technical issues such as poor drillability of rocks, easy well-inclined deep super-thick salt paste layers, development of upper super-thick gravel layers, deep high- pressure and low permeability etc. By applying multiple technologies including strengthened drilling parameters, advanced Power-V anti-inclining tools, optimized composite drill bits and selection of oil-based drilling fluid etc., Zhongman Drilling has completed the Keshen 13-2 Well with a total depth of is 7483m and the construction period of 243 days. This achievement has reached the record of the shortest construction period in the same block. The Dabei 1701X Well was completed at a total depth of 6932m and the maximum well inclination of 61 degrees. By achieving the high speed and high efficiency in this high slope ultra-deep directional well, ZPEC has established an excellent brand image in the Tarim oil field.

copyright © 2021 中曼石油天然气集团股份有限公司 . ALL RIGHTS RESERVED 沪ICP备08116516号-1